Diaper Recycling Technologies

Disposal Alternatives has developed a simple, low cost "PE-Processor" (Plastic Extraction Processor) that runs using very low resource and in a very small footprint.

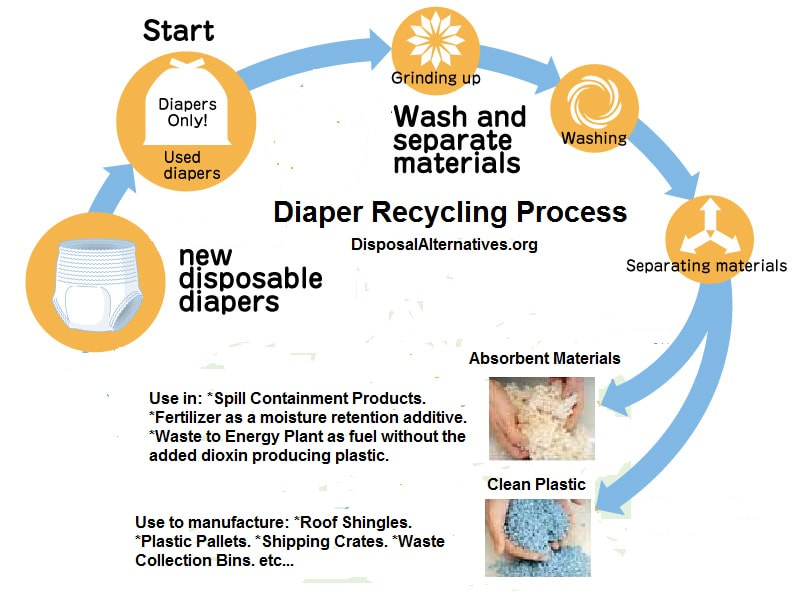

This processor sanitizes the materials, separating the plastic for recycling then after adjusting the pH, will send the remaining absorbent materials to be mixed with manure and used for a highly moisture retentive fertilizer, used in spill containment, or even used as fuel to make energy.

Contact us for more information about our smart and responsible alternatives to landfill.

Here's how it works:

This processor sanitizes the materials, separating the plastic for recycling then after adjusting the pH, will send the remaining absorbent materials to be mixed with manure and used for a highly moisture retentive fertilizer, used in spill containment, or even used as fuel to make energy.

Contact us for more information about our smart and responsible alternatives to landfill.

Here's how it works:

The Disposal Alternatives PE processor

(1) Diapers are collected in sealed-bags or specially labeled collection containers.

(2) Diapers enter the PE Processor.

(3) The clean inner materials are expelled from the diapers outer plastic cover.

(4) The remaining plastic cover is pushed from the machine and ready for the next step.

(5) The plastic covers are collected then turned into pellets.

Example of clean plastic pellets from recycled diapers.

These can be used to manufacture many useful items.

These

These can be used to manufacture many useful items.

These

The PE Processor Diaper Recycling Process

OTHER RECYCLING TECHNOLOGIES FROM AROUND THE WORLD

(with comparisons to the Disposal Alternatives PE Process)

With

(with comparisons to the Disposal Alternatives PE Process)

With

SSEFE

SSEFE has developed a method of recycling used disposable diapers that is fairly simple and recovers a large amount of the diaper's materials. This process has some basic similarities to the Disposal Alternatives PE Processor approach but on a much larger scale. The SSEFE process also separates the polyacrylate from the wood pulp though it uses a larger percentage of energy in the recovery process, while the Disposal Alternatives PE process allows these materials to remain together for use as an absorbent material or fuel.

KnoWaste

Knowaste was originally founded in Canada and has been a pioneer in large-scale incontinence product recycling around the world.

Knowaste's Patent process recovers nearly all of the used materials. The Knowaste process is a completely different approach than the Disposal Alternatives PE Process and if cost is not an issue and plant size can be much larger, it is a more thorough process.

Contact Knowaste for more information on large scale incontinence-product recycling processors.

Knowaste's Patent process recovers nearly all of the used materials. The Knowaste process is a completely different approach than the Disposal Alternatives PE Process and if cost is not an issue and plant size can be much larger, it is a more thorough process.

Contact Knowaste for more information on large scale incontinence-product recycling processors.

Example of UV decomposition process

Our research proves that regular disposable diapers do in fact decompose but they require direct sunlight. The issue is that once landfilled, diapers are literally cut off from what it takes to make them decompose. The clay covering of most landfills actually entombs the waste, severely slowing the decomposition process. It can take up to 500-years for a diaper to decompose in a typical landfill.